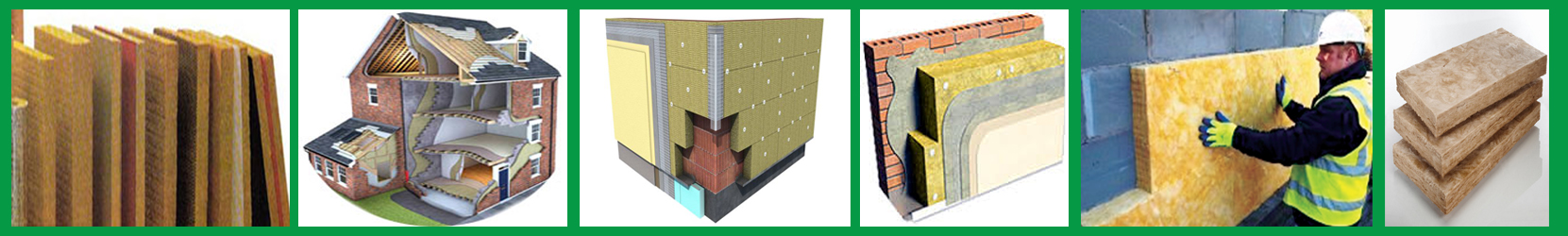

Mineral Wool Slab

Resin Bonded slabs are made up of finely spun fibers derived from selected slag/rocks. Melted at high temperature and bonded with a thermosetting resin, the Resin Bonded Slabs are known for the uniformity of fiber distribution. The fiber laying pattern and diameter of the Resin Bonded Slabs, as well as the bulk density, is properly controlled so as to ensure that the output has the required density and thickness.

All in all, the Resin Bonded Slabs are the ideal combination of thermal insulation, fire protection and sound absorption properties, and their versatility as well as easy transportation and use makes them the perfect choice. With a heat resistance capacity of 400°C and above, the Resin Bonded Slabs can have a modified actual temperature limit and material density.

The Resin Bonded slabs are usable in hot and cold conditions and they ensure convenient heat transfer, with the ideal use being in flat or slightly curved surfaces as well as in the thermal insulation of various walls and panels. These Resin Bonded Slabs are known for their high tensile strength and thermal resistance.

Bonded Slabs are efficiently used in Under Deck Insulation, Air Conditioning Duct Insulation, Sound Proofing of Auditorium, Conference halls, Stadium, Air ports, Furnaces, Ovens, Cable Ducts, Tanks, Autoclaves and Chimneys, DG sets, Solar & sandwich panels etc.

Bonded slabs are preferably used in Commercial buildings viz. Malls, Hotels, Hospitals, Multiplex, Airports, Residential Townships etc. to give better sound proofing. LionRock Insulation provides thermal comfort to users and save energy by way of reduced electricity bills & complements the air conditioning effect.

| Standard Densities* | : 48, 64, 96 & 144 Kg/m3 |

| Service Temperature | : up to 750°C |

| Standard Thickness** | : 40, 50, 60, 75 mm |

| Standard Size | : 1000 x 500 mm

: 1200 x 750 mm |

- Longer life, permitting re-use after removal during maintenance.

- Higher thermal performance, as it is made out of rich siliceous LionRock.

- Environment friendly, as there is no feathering (which normally pollutes the environment).

- Uncontaminated, as manufacturing is totally a DRY Process.

- Non-wicking.

- Superior compressive strength.

- Excellent resistance to vibration & jolting.

- Excellent thermal & acoustic with Fire Protection

- Non-Combustible

- Water repellent

- Excellent thermal resistance

- Chemically Inert

- Negligible Chloride Content

- Energy Conservation & fuel saving

- Ease of application

- Cost effective

- CFC & HCFC Free